Bryk is one of the leading and most modern manufacturers of tools, for the furniture, automotive and aerospace sectors in Poland. Successfully implementing the assumptions of industry 4.0.

Witold Bryk, the owner of the company, will tell us how to build a modern enterprise based on proprietary solutions.

Bryk was founded in 2000. What was its origins and where did the idea of producing tools come from?

The whole adventure with the production of tools started by coincidence. During the fifth year of my studies I was employed as a sales representative and started selling Italian tools in south-eastern Poland. After completing my studies I had two options: to work as a bridge builder or to take care of service and production of tools. The Italian company I represented signed a contract with me, and that’s how I became involved with the industry in which I still work today. At first the company was involved in sales, but when in 2001 it turned out that there were only two shelling shops in Poland, we expanded our activity with service, and together with our brother we opened another one. After 5 years we decided to start producing our own tools. Using the company’s resources, we built our production facilities and started to equip our machine park. At the beginning of our activity, our customers were companies connected with the furniture industry, such as Black Red White, Bog-Fran or Nowy Styl. Thanks to them we have developed our wings. Currently, the company is mainly engaged in the production of diamond and carbide tools, also for the automotive and aerospace sectors.

You are carrying out a project for shaping micro and macro-geometry of tools made of super-hard materials in the process of implementing advanced laser techniques. What are the assumptions of this undertaking and at what stage are you at present?

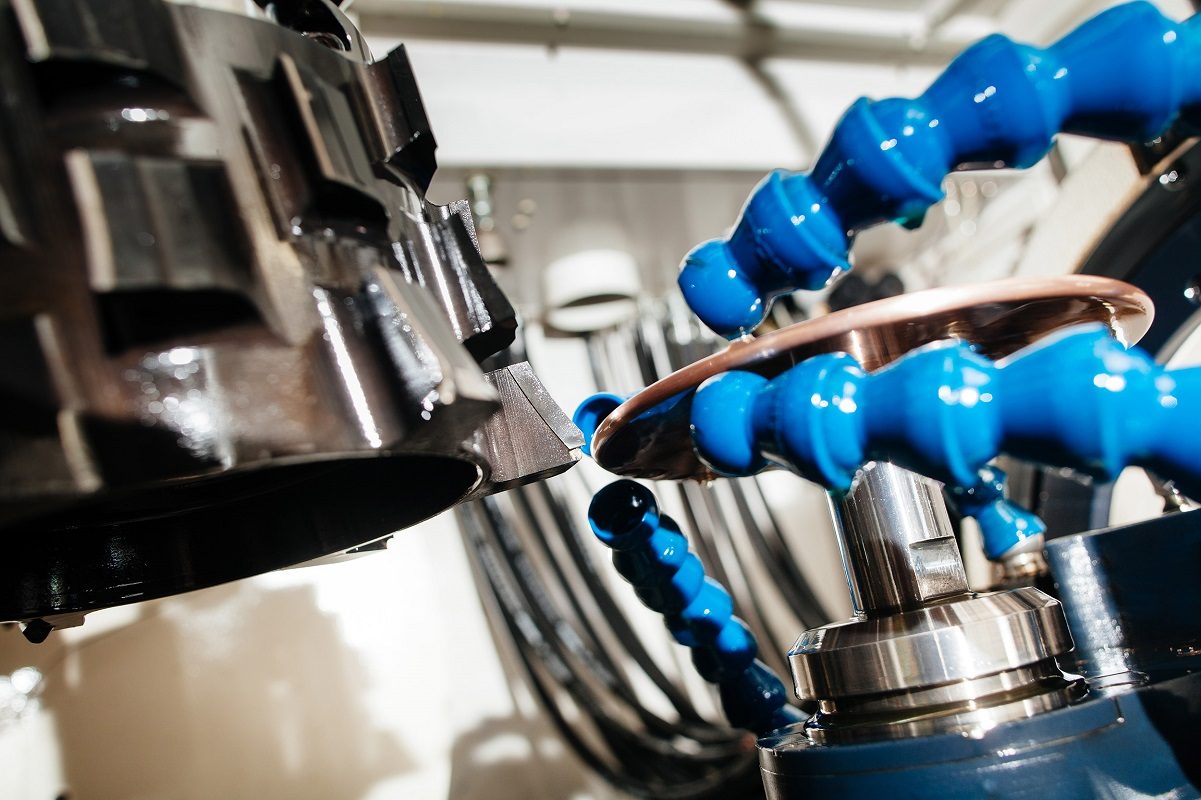

Our main objective is to develop technology related to the production of both diamond and boron tools. For this purpose, we want to apply to our production laser technology, which has been present on the market for several years now. The initial stage of the project involved the identification of technology and production methods, which was facilitated by the Cracow University of Technology, Rzeszów University of Technology and company Erko. Currently, we are in the process of building an appropriate stand, and selecting devices and components that will allow us to implement new tool solutions with the use of diamond and boron blades. Today, we are the only company in Poland with domestic capital that implements such a solution. Laser technology is very modern and fits into the assumptions of industry 4.0. We planned to complete this project at the beginning of 2019, however, due to the postponement of the date of signing the contract with the National Centre for Research and Development, its implementation will be delayed by about six months.

At the same time, you are working on the implementation of a new diamond tool technology for the furniture industry. Please tell me what this project is all about?

The purpose of this project is to develop the product offer addressed to the furniture industry. Five years ago, I was able to invent a new type of tool, which I applied to the patent office. After four years we received a patent, on the basis of which we want to create new products. This project mainly involves investment in machinery in order to improve and automate the entire production process. The projects we carry out are a consequence of forward-looking thinking, which is why we try to focus on the continuous development of technologies and assumptions that fit in with the concept of industry 4.0. In total, we implement 12 projects, not only as their leaders, but also as partners of other companies, such as PZL Mielec, WSK Rzeszów or Poltra. Due to the continuous development and investment in production facilities last year, within the framework of EU funds and own funds, we started the construction of a new plant.

You have established cooperation with business partners from Italy, Germany, Northern Ireland, Japan or South Korea. How did this happen?

All business contacts with foreign contractors are a natural consequence of the travel and talks we have had. At the beginning, these trips were mainly related to Italy, which we visited on average 2-3 times a month. Soon, thanks to the contacts made at the fair, we were able to travel to Japan, China and Korea. In Japan we have started cooperation with one of the biggest and most top tool company in the world, which is Kanefus. We treat the issue of export first of all with perspective, because it is not yet developed enough in our company to talk about some large share in sales. For several years now, we have been systematically implementing certain measures on foreign markets in countries such as Belarus, Slovakia and more recently in the United States.

Interviewed

Błażej Pezdek